Thermo Fluid Dynamic Design of a 4-Way Reversing Valve

OUTLINE: Supply new 4-WAY reversing valves for R744 trans-critical heat pump.

TECHNOLOGY: CAD/CFD/FEM

Our customers are global Japanese manufacturers specialized in highly energy efficient electric heat pump and water heaters for domestic, industrial and commercial use. Instead of the more conventional ammonia or fluorinated refrigerants and hydrocarbons, supercritical carbon dioxide is used as a refrigerant: this technology offers a means of energy conservation and reduces the emission of greenhouse gas.

They are engaged in constant re-engineering of their control valves for catering to the needs of developing markets. One such valve is required to working pressure up to 120bar and under the full differential pressure of the heat pump system (70bars). The customer asked us to verify Kv, capacities and temperatures attained by critical components of the new developed design using numerical simulations.

PREMISES: The European Legislative Framework

In 2007 EU leaders endorsed an integrated approach to climate and energy policy that aims to combat climate change and increase energy security while strengthening its competitiveness. In 2008 the European Commission proposed binding legislation to implement the 20-20-20 targets. This “climate and energy package” became law in 2009.

The 20-20-20 targets by 2020 include:

• Reduction of EU GHG emissions by at least 20% below 1990 levels;

• 20% of EU energy consumption to come from renewable resources;

• 20% reduction in primary energy use compared with projected levels, by improving energy efficiency.

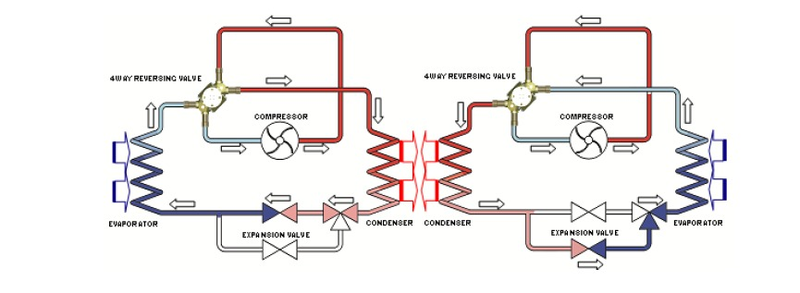

PREMISES: The Heat Pump Technology

Renewable energy is generated from natural resources such as the sun, wind, and water, using technology which ensures that the energy stores are naturally replenished. By adding a small amount of drive energy, a heat pump can move heat from a low temperature to a high temperature. This means that the same piece of equipment can be used to remove heat from a space (cooling) at one end while at the same time adding heat to another space(heating).

The most prevalent use of heat pumps is for cooling, e.g. the common household refrigerator or air conditioner, but increasingly heat pumps are also used to upgrade heat to useful heating temperatures.

PREMISES: The heat pump efficiency

The more efficient a heat pump is the more cost-effective and less energy consuming it will be.

The COP, or Coefficient Of Performance, describes the efficiency of the heat pump and is defined as the ratio between the useful heat transfer for heating or cooling and the required drive energy. The useful energy can either be heating or cooling energy depending on if the heat pump is used to provide heating or cooling.

There are a number of factors that will affect the efficiency of a heat pump.

Major improvements in the efficiency of heat pump systems have been

achieved through developments in the fields of heat exchangers, compressors, motors and components.

PREMISES: Components actually on the market

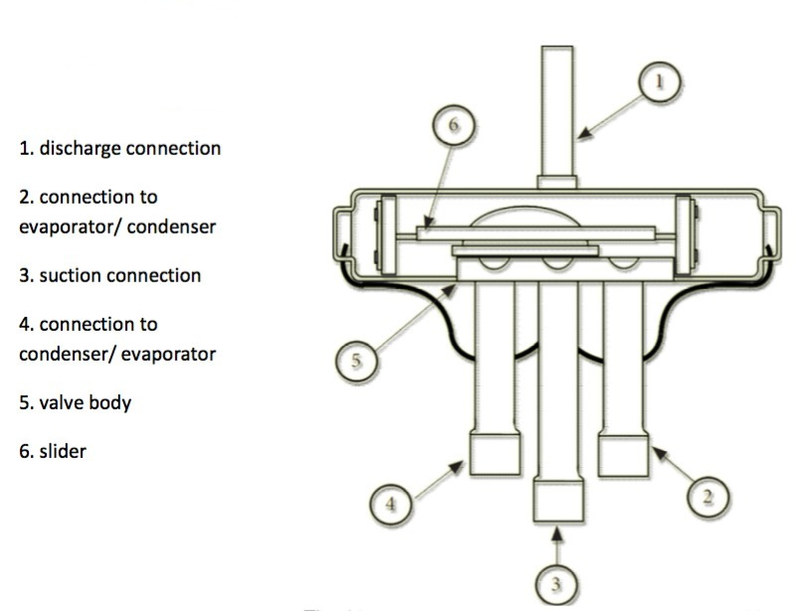

The 4-Way valves actually on the market are solenoid operated reversing valves — slide type with pilot valve, made up of three basic components

- pilot valve

- main valve body, including valve slider

- solenoid coil

The 4-Way valve slider is shifted by changes in differential pressure in the valve which is actuated by the pilot solenoid valve.

Principles of operation in cooling and heating cycle are quite elaborate.

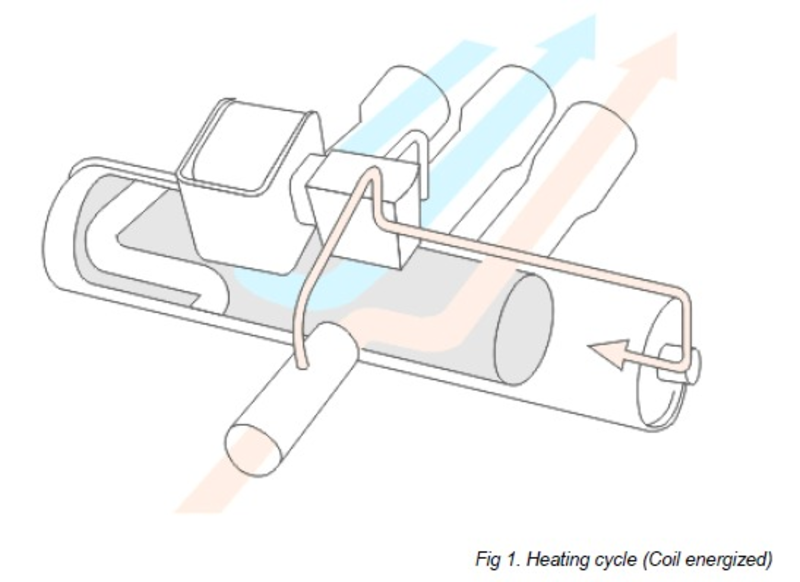

Winter conditions

When the solenoid coil is energized (Fig 1), the pilot valve moves to the right, and the high pressure fluid enters into the piston chamber. On the other hand, the fluid is released from the piston chamber, and the piston and the slide valve portion moves to the right.

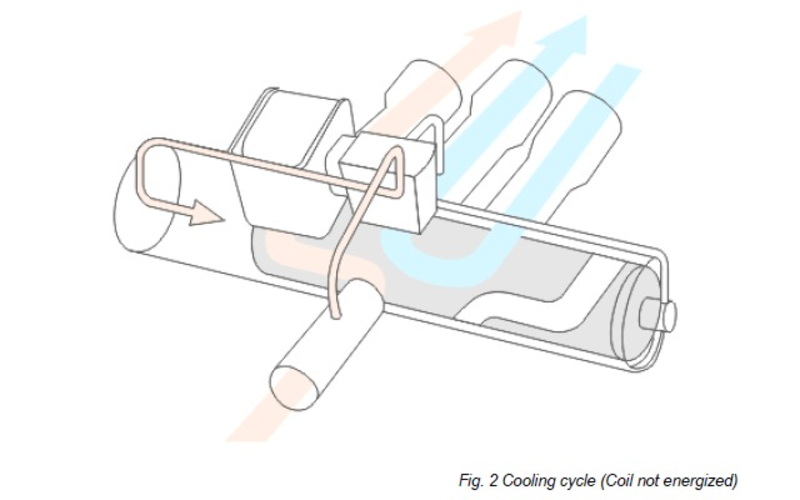

Summer conditions

When the solenoid coil is de-energized (Fig.2), the pilot valve moves to the left, and the high pressure fluid comes into the discharge capillary tube, and enters into the piston chamber. On the other hand, the fluid is released from the piston chamber, and the piston and the slide valve portion moves to the left.

Limits in use

Due to the rather sensitive technology of the movement of the slider, that works by a pressure differential regulated by a solenoid operated electric valve, such valves present many limits of use, as in user’s instruction manual:

1. installation is possible for 4-Way reversing valve only in horizontal position, the orientation should be in the range from 0° to 180°; in vertical position, the valves can be installed in any orientation as long as the coil stem position is up.

2. Before installing, thoroughly clean the inner part of pipes to prevent dust or dirt particles from entering the valve. Use 80 to 100 mesh strainer at the valve inlet, if dust or dirt particles inside the pipes may flow into the valve.

3. Do not heat up the body to a temperature higher than 120°C when soldering the joints. Soldering must be carried out with the coil removed.

4. Do not suspend the valve by the lead wire of the solenoid coil or handle it violently

5. Do not wrap up the solenoid coil with thermal insulation. This could cause the coil to overheat and burn out.

So for the coil:

1. Make sure the supply voltage conforms with the voltage marked on the coil enclosure (or label).

2. When mounting the solenoid coil, the enclosure fixing bolt must be tightened firmly.

3. When wiring the solenoid coil, leave enough slack to ensure that no stresses are applied to the supply wires and coil connection.

4. When removing the solenoid coil from the body, be sure to cut out the supply power. When you keep the coil energizing itself for an unnecessary time, the coil might burn out.

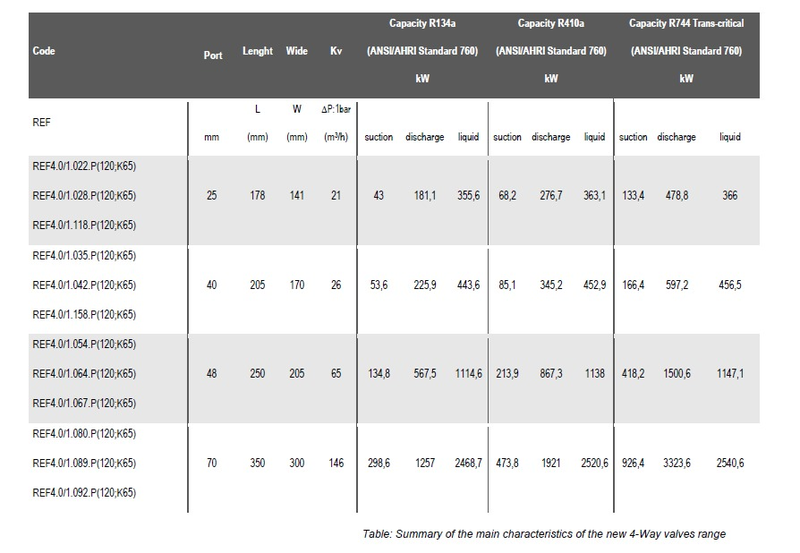

PROJECT: 4-WAY INVERSION VALVES FOR R744TRANS-CRITICAL HEAT PUMP

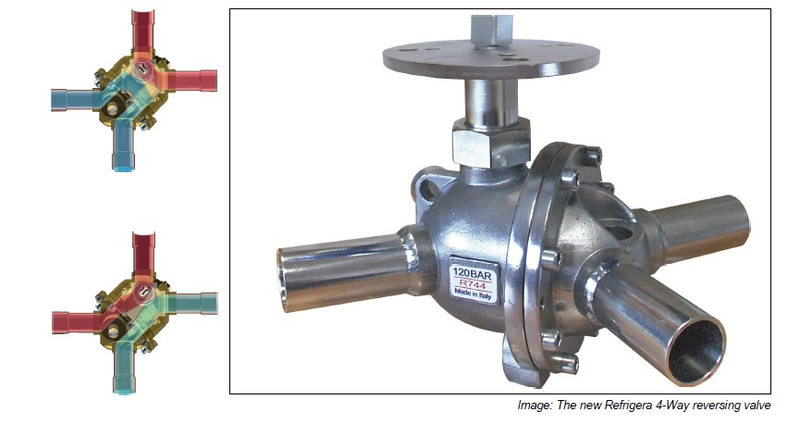

The Refrigera 4-Way Reversing Valve is the key component to provide Heating and Cooling by reversing the flow direction of refrigerant. Valves are suitable for all P.E. Directive Group 1 or 2 refrigerants and operate under the full pressure of the heat pump system. The cycle inversion needs no solenoid pilot valve and no slider movement, reducing risk of mechanical seizures due to environmental conditions, presence of dirt or

particles. Moreover, in comparison with the solenoid piloted valves, where the pressure differential regulates the movement of a slider, which changes the direction of the refrigerant, the ball-valve design guarantees minimum pressure drop and very low risk of leakage, prevents the fault to not complete changeover opening /closing cycle and ensures quick changeover, even without any pressure differential: the ball is suspended by 4 Teflon seats is able to perfectly works even at maximum temperature or even in case of total absence of pressure in the system.

The quality and the design of this new component were carefully designed to guarantee safe and endurance at highest working conditions. Stainless Steel body and connections assure high performance even in the wide range of R744 applications. As an option, Refrigera can supply the valve mounting CuFe2P tubes, with socket welding connections. ISO5211 Flange, purposely burst-proof designed for heavy duty HVAC applications, allows easy coupling to every actuator model on the market.

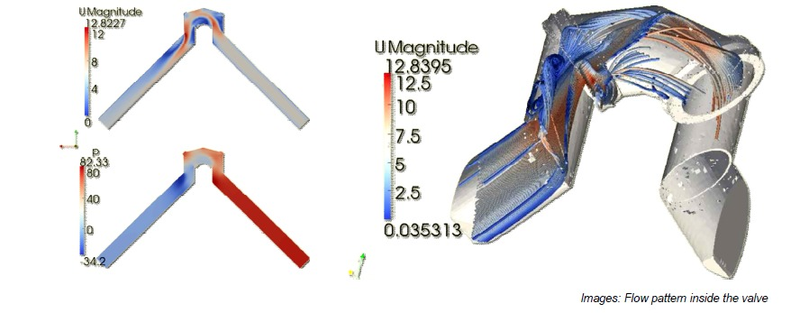

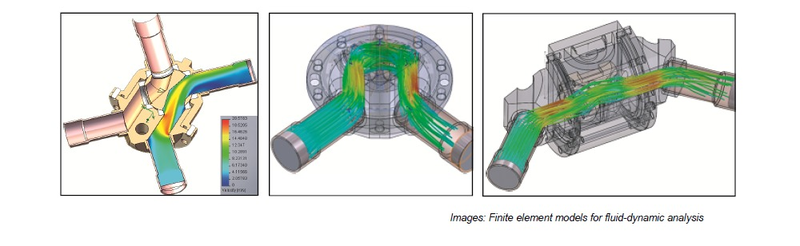

PROJECT: CFD SIMULATIONS

The challenge to ensure appropriate flow-sections in both opening configurations was won in close partnership between Refrigera and the International School of Doctorate in Environmental and Industrial Fluid Mechanics of the University of Trieste and the IEFLUIDS Laboratory, that tested new 4-Way entire range by CFD software and Refrigeration Capacities for all the diameters, with an appropriate theoretical support. IEFLUIDS performed hydraulic analysis by means of OpenFoam CFD software. The simulation was carried out using a RANS k-epsilon model through in-house developed wall functions for the proper resolution of the Boundary Layer near the solid walls of the domain. Results were used to check the design of the valves: Kvs are maximized for each diameter.

PROJECT: RESULTS

Customer was provided with flow coefficient Kv and Capacities (kW), related to the most popular synthetic refrigerants and R744 of the valve, according to ANSI/AHRI Standard 760-2007. The loss of pressure as the

flow moves inside was analyzed. Temperatures at various components were reported to customer. The flow patterns were used in FEM modeling to check Structural analysis: all sections were found to be within the

operating limits of the materials.

PROJECT: SUMMARY

Refrigera, with its new 4-Way Reversing Valves, wants to offer an alternative to the current market and an innovative product developed in a wide range of connection sizes and special configurations and capacities,

fully compatible to Natural Refrigerants for installations with low environmental impact (up to the nominal diameter 32, valves have been designed to work in Carbon dioxide trans-critical cycle PS120 bar (90bar

differential pressure).

There is a line specifically compatible to unsaturated HFCs, or hydroflouroolefins (HFO), that have been developed as another viable options for long-term replacement of the synthetic CFCs and HFCs, used as single substances or in mixtures with HFCs. Refrigera 4-Way Reversing Valves are a EC approved products according to 97-23-EC – Pressure Equipment Directive.

PROJECT: DEFINITIVE ADVANTAGES

In respect to a solenoid operated reversing valves-slide type with pilot valve, Refrigera new 4-Way Reversing Valves grant:

-better resistance in handling;

-easier to assembly;

-more intuitive to positioning in the system;

-more reliability in use;

-higher Kv factor;

-inclined position allowed;

-easier to clean, even in the event of compressor burnout;

-better ability to work in extreme environmental conditions;

-no risk to preclude functionality in case of underestimation of the

capacity in the design phase;

-reliable function even in the absence of pressure in the system;

-no risk of incomplete changeover;

-lower seizure risks in presence of dirt in the flow;

-possibility of use as a mixing valve.

- Browse by:

- Technology

- Products

- Industries